When a storm caused severe flooding in North Balwyn, Plumbtrax Infrastructure Services turned to the Cosmic C500 crawler to tackle the blocked stormwater pipe — delivering a fast, efficient solution with minimal disruption.

Plumbtrax Infrastructure Services (Plumbtrax) has earned a reputation for tackling complex plumbing and drainage projects, particularly in UV CIPP. The company’s investment in cutting-edge pipe rehabilitation equipment, including the Cosmic Engineering (Cosmic) C120 and Cosmic C500 crawlers from Pipe Core, has given it the flexibility and capability to take on some of the most challenging pipeline renewal projects.

In early March 2025, the Plumbtrax pipe rehabilitation team was called to North Balwyn after a storm caused significant flooding in a residential area. Residents had reported overflowing pits to the council, and the cause was traced back to a DN600 stormwater pipeline located in a council easement behind several properties.

“After a severe storm, residents reported overflow from a nearby pit, prompting the council to investigate,” the Plumbtrax operator said.

Upon inspection via one of two 450mm x 600mm manholes along the line, the team found multiple displacements and root intrusions at the pipe joints. While some of the roots were cleared using a chain knocker, others were too large and required milling before any relining could take place.

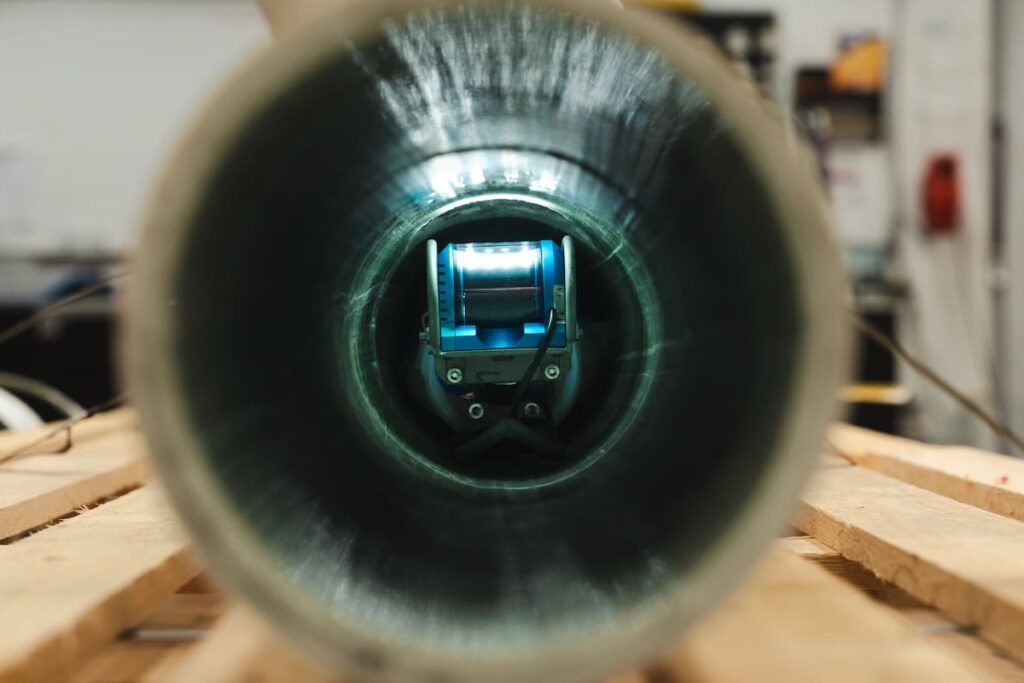

The DN600 pipeline called for the heavy-duty Cosmic C500, its first major test since joining the Plumbtrax fleet. Plumbtrax had been waiting for the right project to put this heavy-duty system to work, and North Balwyn provided the perfect opportunity.

The crew deployed the C500 from their custom-fitted van, which features a built-in slide to move the system in and out of the vehicle, as well as a dedicated water tank to keep the electric cutting unit of the robot cool during operation. Lowering the robust system into the pit with an excavator and winch, they prepared for an intensive multi-day rehabilitation process.

The Cosmic C500 was tasked with trimming the larger intruding roots, installing patches, cutting out two house connections, and performing a final clean after relining. Over four days, the Plumbtrax crew worked efficiently to complete the job, which also included high-pressure cleaning and CCTV inspections.

Plumbtrax highlighted the importance of the right equipment for these types of projects and explained the council’s reasonable project expectations.

“When working for the council, safety is a priority. This allows our team to operate efficiently without the pressure of unrealistic deadlines,” the Plumbtrax operator said.

Plumbtrax relies on Cosmic’s relining materials and supply of these from local distributor Pipe Core, ensuring consistency across all their projects. While the team frequently uses the C120 for smaller-diameter pipes, they found the C500 to be just as user-friendly but for larger-scale applications.

“We use the C120 a lot, it’s easy to get the hang of,” the Plumbtrax operator said.

One feature the team particularly appreciated was the Cosmic system’s cleaning lens jets, which provide clear visibility even in tough conditions.

“It’s one of my favourite features of both the C120 and C500,” the Plumbtrax operator said. “The lens is cleaned through small jets, which is great when grinding out concrete. It’s controlled manually from the operator’s station.”

Efficiency was also key. With Cosmic’s fast-curing patches, the team minimised disruption to the surrounding residents.

“Patching with the Cosmic system is one of the quickest methods for us. The patches we installed only took 10 minutes to cure and will increase the pipe’s lifespan by up to 50 years,” the Plumbtrax operator said.

With the North Balwyn stormwater system fully restored, Plumbtrax has once again demonstrated its ability to execute high-stakes rehabilitation projects with precision.

The company’s investment in the Cosmic system, backed by Pipe Core’s supply and support, positions it at the forefront of pipeline rehabilitation, ready for the next challenge.

This article was originally published by Trenchless Australasia and has been republished here with full permission. All content, including images and text, remains the property of Trenchless Australasia.