Through its partnership with Pipe Core, PipeTech is utilising Cosmic Engineering technology in its UV relining offering.

PipeTech has been operating throughout New Zealand for over 20 years, specialising in innovative pipeline rehabilitation solutions.

“We saw an opportunity to increase business efficiencies and deliver reliable, long-term solutions for our clients.”

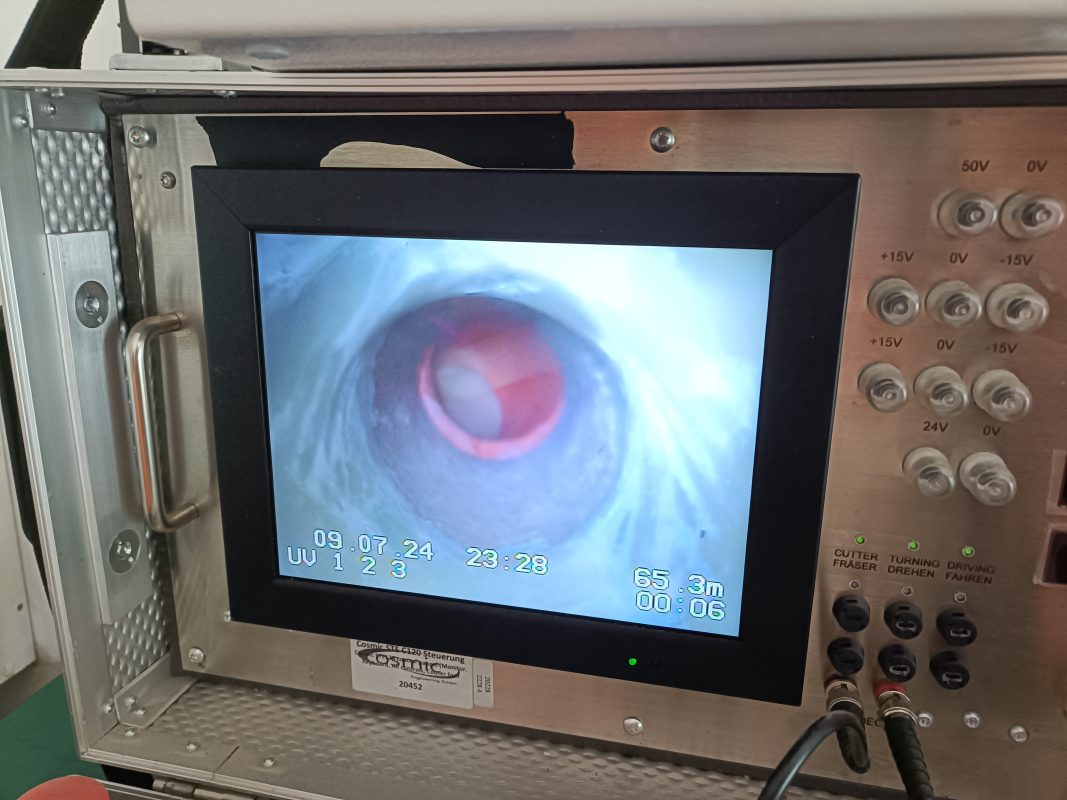

Included in their UV relining offering is junction rehabilitation – a tophat system used to renew junctions and lateral connections to the mainline. This system has been revolutionised with the launch of the Cosmic System from Cosmic Engineering GmbH to the Australasian market.

PipeTech has recently upgraded its system and acquired the new Cosmic C120 crawler for DN 120 – DN 600. This system is a versatile modular robot crawler that can be used for inspecting mainlines and lateral connections, robotic cutting, and installing UV cured patches and tophat junction seals.

The junction sealing material used is a GRP material that is non-shrinking, fast curing, and self-supporting. Most importantly it also has an expected technical design life of 50 years.

PipeTech has been using this technology significantly in and around Papakura, Auckland and has been responsible for hundreds of tophat installations through a 10-year working relationship they have held with their client Veolia New Zealand.

“We have an excellent working relationship with Veolia, and together we have successfully delivered projects for various asset owners across New Zealand,” PipeTech managing director Rowan Burgess said.

“We saw an opportunity to increase business efficiencies and deliver reliable, long-term solutions for our clients.”

“Our team was impressed with the thorough training conducted by Pipe Core and have since been very happy using the system,”

Many local councils are shifting towards a proactive installation-focused approach rather than a reactive one, incorporating innovative techniques like junction sealing as part of mainline renewal projects.

“We see many issues with infiltration at the joints and lateral connections, especially in older pipes, and recognise the benefits of investing in the infrastructure now, especially where works are already being undertaken on the mainline,” Burgess said.

Cosmic Engineering’s unique technology is ideal for quick, efficient, and safe rehabilitation to all types of pipes.

PipeTech installs Cosmic seals and patches in all pipe types, including asbestos cement, earthenware, concrete, and lined pipes.

“We also benefit from using Cosmic’s pre-manufactured materials, which ensures consistent quality during installation and no mess on-site,” Burgess said.

PipeTech relies on Pipe Core, the exclusive distributor for Cosmic in Australian and New Zealand, for technical support, and material supply.

“One of the biggest benefits of this system is the ease of access to materials. Madeline Galbraith, account manager at Pipe Core, is always on the front foot to give us updates about stock and availability to ensure we are never caught short.”

Galbraith said the company has a steady supply of Cosmic materials entering the country to ensure its customers have easy access, especially for quick response jobs.

PipeTech also conducted hands-on Cosmic training through Pipe Core, who are available for ongoing support.

“Our team was impressed with the thorough training conducted by Pipe Core and have since been very happy using the system,” Burgess said.

“The true benefit of the system is seen through the quality of the lining product and the speed of installation and curing"

The team of three, normally onsite for a day of tophat installs, operates out of customised Box Body Truck and uses a small winch system or the team to manually lower the robot into a pit.

The team gets started by cleaning the lines with high-pressure water and a CCTV inspection.

Generally, the actual location of the lateral connection has been pre-surveyed, and the innovative Cosmic robot uses these location details to drive into position, locate the junction, and make the tophat installation.

“The true benefit of the system is seen through the quality of the lining product and the speed of installation and curing, which is between seven to ten minutes,” Burgess said.

“The UV light technology delivers rapid curing on site, which means we can install more tophats in a day.”

“Our most impressive effort is thirteen tophats in one day, but we would normally average between eight to ten.”

With the combination of advanced technology, reliable materials, and thorough training, PipeTech continues to lead the way in providing innovative and efficient pipeline rehabilitation solutions across New Zealand.