Tackling severe stormwater infiltration, Clearflo Specialised Services deployed SAERTEX LINER and Rausch RRcure 100 SE for a critical TAFE Queensland infrastructure upgrade.

A major stormwater rehabilitation at TAFE Queensland Eagle Farm Campus saw Clearflo Specialised Services overcome extreme root and concrete infiltration using advanced trenchless technology from SAERTEX multiCom• and Rausch Rehab, delivering a long-term structural solution with minimal disruption.

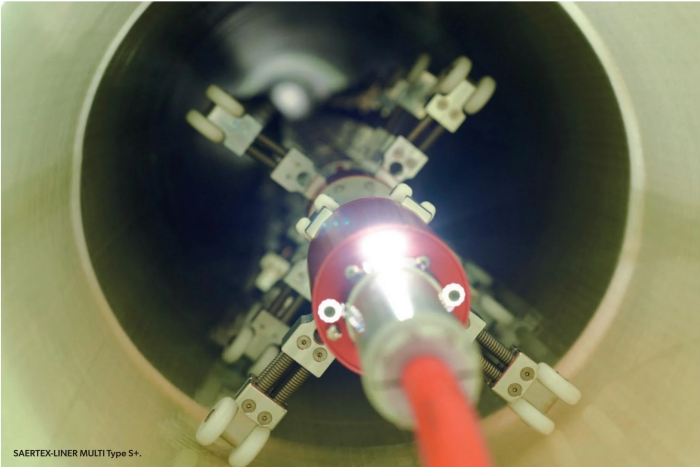

This was one of the first stormwater rehabilitation projects in Queensland to use the SAERTEX-LINER" MULTI Type S+ Standard in combination with the Rausch RRcure 100 SE UV system, technologies available in Australia and New Zealand.

When Clearflo Specialised Services was awarded the contract to rehabilitate 450m of deteriorated stormwater pipe at TAFE Queensland Eagle Farm Campus in Brisbane, the crew faced some of the worst root and concrete infiltration they had ever encountered.

With support from Pipe Core and access to innovative technology from Rausch Rehab and SAERTEX multiCom, Clearflo Specialised Services delivered a structural renewal solution which the manufacturer said has a technical service life of 100 years, setting a new benchmark for trenchless rehabilitation in complex high-traffic sites.

The site, located in Brisbane's eastern industrial hub of Eagle Farm, was experiencing major stormwater blockages. More than 90 percent of the pipe network was obstructed, choked by invasive roots from large Moreton Bay Fig trees along with severe concrete in the lines.

Clearflo Specialised Services Owner John Farrugia said he had never seen such severe infiltration.

"We had over 200m of tree roots to cur before we could even clean the line properly," he said.

To overcome the challenge, Clearflo Specialised Services engaged TOG Environmental, an experienced specialist in asset investigations, renewals, and maintenance.

They conducted high-pressure robotic cutting and ultra-high-pressure water jetting to clear the obstacles. Once the area was cleared, the relining program could begin, carefully staged to maintain access and minimise disruption to operations for TAFE Queensland.

Throughout the project, Clearflo Specialised Services maintained close communication with TAFE Queensland facilities staff, who commended the crew's professionalism, safety protocols, and ability to keep the site accessible during term time. Temporary fencing was erected around access chambers and pedestrian paths to ensure safety.

Over a four-week period, the crew rehabilitated multiple sections of pipe, relining one lane at a time. Conduit lengths ranged from 15-68m, with diameters from DN150-300. The crew also completed multiple junction reinstatements and relined over 100m of DN450 mains using SAERTEX-LINER MULTI Type S+ Standard, a glass-reinforced liner from SAERTEX multiCom, cured using the Rausch RRcure 100 SE UV system.

The liner was chosen for its long technical service life - which SAERTEX has independently rested to 100 years – structural performance, and chin wall thickness, making it an ideal march for confined spaces and approved for use in Queensland.

"SAERTEX multiCom has been great to work with," Farrugia said. "Their ream is upfront about what the product can and can't do. Thar transparency helps avoid project risk and builds trust."

To support the project, Clearflo Specialised Services invested in the Rausch RRcure I00

SE, a self-contained UV curing system available through Pipe Core. Designed for diameters between DN150 and DNl000, it's well-suited to access-limited sires like schools and carparks.

"The size of the RRcure I00 SE is what appealed to us," Farrugia said. "It fits into right spaces. We've now completed eight jobs with it, and this TAFE Queensland project was the first time it was used consistently across four weeks."

To streamline operations, Clearflo Specialised Services custom-built a van with a ramp to house the curing system, enabling quick and safe deployment on sire.

Founded in 2000, Clearflow Specialised Services has grown into a multi-vehicle operation. The crew has continually invested in training and upskilling to ensure operational confidence and system reliability.

"We sent a crew member to Germany for hands-on training with the Rausch Rehab system," Farrugia said.

This project also supported workforce development, with a Queensland-based crew completing certified theoretical and practical training in SAERTEX-LINER" installation method for both gravity and pressure pipe systems

"Knowledge is power," said Farrugia. "The more we understand the system, whether it's fault finding, terminations, or diagnostics, the less downtime we have and the less frustration for the crew."

"The ability to access global expertise combined with local support has been a key part of the project's success. Having that level of support available has been invaluable. The industry is moving forward thanks to this kind of innovation and collaboration."

Project benefits included:

- Long-term durability with an expected technical service life of 100 years

- Trenchless installation with minimal community disruption

- Improved flow capacity of stormwater network

- Fast, efficient, UV-cured liner installation

- Compact equipment easy to use in restricted areas

- Efficient scheduling with reduced site downtime

- Local upskilling and capability development

Despite the intensive preparation required to clear the stormwater lines, the project was delivered on time and within budget. Most importantly, it future-proofed a critical asset in Brisbane's stormwater infrastructure, ensuring the sire is compliant and ready for redevelopment.

For more information, visit pipecore.com.au